Although 3D printing was quickly popularized, with many makers wishing to print various objects directly from their homes or a fablab, leading to more than 500,000 consumer printers in 2016 (source: Le Monde), the wind has now turned. Sales of BtoC printers tend to slow down, while manufacturers in every sector (automotive, aeronautics… and fashion) have developed new work methods and projects to capitalize on the promises of these disruptive technologies. The market for additive printing increased by 25.9% in 2015, reaching the value of 5.165 billion dollars, and is growing by about 30% in recent years.

Today, we offer you a quick overview of 3D printing in the fashion and luxury industries. And we promise we won’t talk about the Adidas FutureCraft project!

3D PRINTING AND LUXURY

“3D allows luxury to return to uniquenes,” said Catherine Gorgé, General Manager of Prodways, at a roundtable on that specific topic durant the FashionTech Festival.

Indeed, if the first experiments were as impressive as they were rare, carried by artists such as Iren Van Herpen or Behnaz Farahi, digital printing technologies have today become real levers to re-enchant communication, products, and customer experience which are so important and special to the luxury industry.

3D printing is also about to change the world of accessories: it is used to print molds with extremely fine and precise patterns allowing new designs of jewelry. Jweel, for example, is a website that allows customers to draw their own jewelry, or to customize existing models that will then be printed in 3D. Another example, better known, is the French start-up Gemmyo, using 3D printing to allow everyone to personalize jewels: the user can thus visualize on the site thousands of possible combinations before choosing his favorite.

APART FROM LUXURY, CAN TECHNOLOGICAL ON-MEASURE BE ACCESSIBLE?

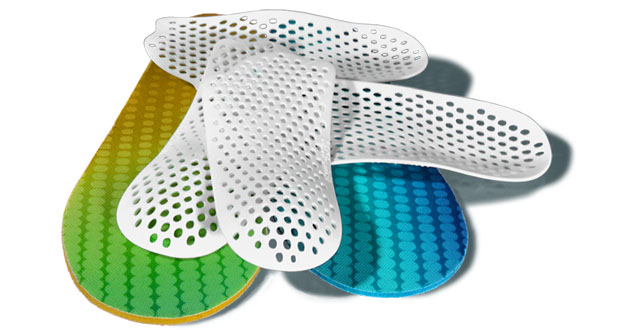

But this alliance between 3D printing and personalization knows many other applications: True Gault, in the USA, offers footwear made on demand after a 3D scan of your feet, when Scientifeet (French startup in partnership with Prodways) adopts a vision more medical, with its tailor-made soles correcting the posture.

Finally, we cannot fail to mention Endeer – one of our season 2 startups – in this article! Incubated in Look Forward for almost a year, this startup co-founded by Claire Chabaud and Mathilde Alloin puts 3D printing at the service of women, offering support caps that are totally tailored for printing in a flexible polymer. With the key, more support, comfort, but also reduced risks of developing breast cancer … 3D printing is therefore not only an opportunity to personalize parts, but also enrich the textiles and clothing for medical purposes, or to adopt a healthier lifestyle.

BRAKES ARE YET TO BE REMOVED TO 3D PRINT CLOTHES

The main problem when talking about 3D printers and clothing remains the raw material. Although experiments are currently being carried out on many materials (wood, bronze), textile materials such as cotton and linen are still very little used. Now, if you can now customize accessories, 3D printing of clothes remain today a long-term goal.

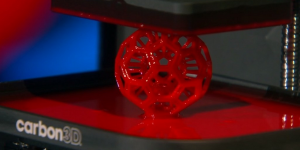

More than the materials involved, the technology must also be refined to allow creators to appropriate and experiment with 3D printing. If the first printed objects are always remembered, with rough and inaccurate finishes, many efforts have already been made: radical innovations such as photopolymerisation printing (in place of extrusion) have appeared in the last 3 years, allowing:

- A rarely achieved accuracy, approaching thread weaving,

- More flexible materials, with a softer feel, closer to worn objects

- A drastic reduction in production times!

However, in the case of large collections, 3D printing remains way slower than thermo-molding …

Several other brakes still exist, even beyond the price of materials, in the minds of consumers: thus, the term 3D printing itself remains an unused term, which can frighten and intrigue non-technophiles. Moreover, the democratization of these technologies via personal printers has been a great success, but also inclined consumers to think that the products resulting from the 3D printing remained “amateurs”, with a finish and details that can be unsatisfactory … Here is where the stakes of the startups and big companies cited above lie: succeeding in convincing of the interest and quality of 3D printed clothes and items.

Danit Peleg, one of the pioneers in the printing of real clothes, launched 3 months ago the first customizable and printable 3D collection. But costing 1,500€ a jacket, the uses and materials have yet to be mass-marketed before being able to imagine a world where to print one’s clothes at home is a reality for all…