In order to better understand the issues and what is at stake in the textile and fashion industry, we are launching a new series of articles about the influence of digital within these sectors.

If today, the fashion industry has widely evolved in its ways of distributing, advertising and selling clothes, the digital revolution has not touched the production processes yet. Innovations in the field are numerous though, and cover a wide spectrum of activities in the industry.

Computer-assisted creation, fully reinventing itself

Of course, the textile industry has not waited the last few years to embrace the possibilities offered by the computer and internet expansions. Nevertheless, the latest technological trends may have been among the most important: the digital industry, also called industry 4.0, announces profound production paradigms changes with the next few years.

First, computing powers are in constant progress, and 3D simulations are more and more convincing, due to the apprehension of textile textures, thus allowing designers to directly create in 3D. In France, the leader of 3D simulation, Dassault Systèmes, launched in 2010 the FashionLab to work on these matters. With 2 residents designers, Julien Fournié and François Quentin, the company is willing to revolutionize the way we create clothes through the use of 3D avatars – whether they are fitted to you own measures or not –, but also help creative minds to imagine new clothes in a faster, less complicated way for smaller, personalized collections.

3D Printing & new production processes

But all these digital improvements are useless without technical innovations: cutting machines are faster and faster, and the growth of textile spaces in every French or international fablabs is allowed thanks to the democratization of such machines, as Lectra’s, a French worldwide champion in this activity. Thanks to these cost-sharing structures, fashion enthusiasts and small creators can create new clothes and collections easily and at less costs.

New technologies, such as 3D printing, also have a card to play and might lead towards a decentralization of production. New tools are able to print leather, iron or gold, and might be used both for clothes and accessories. The only limit is now the creativity of fashion designers, with personnalities like Iris Van Herpen, Hannouk Wisprecht, Frnacis Bitonti and others leading the way.

Connected textiles, a first step towards traceability and counterfeiting fight

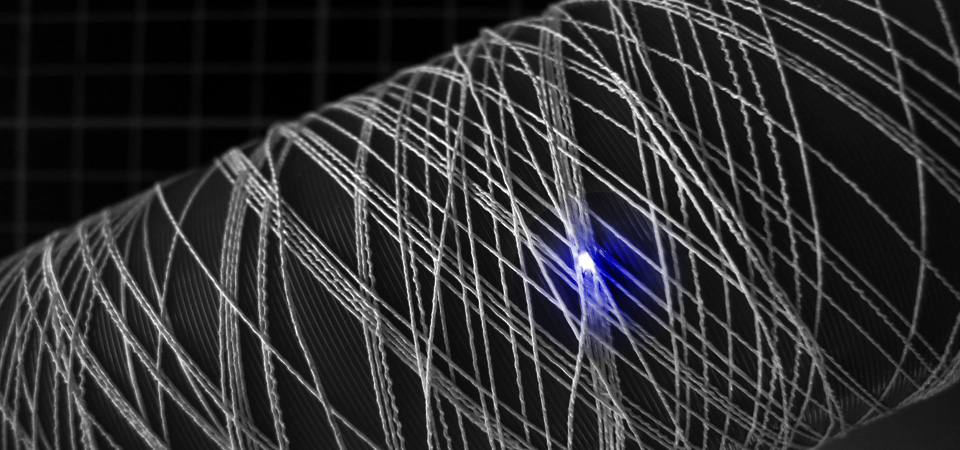

Furthermore, initiatives are more and more numerous about the integration of connected fibers directly into textile. If these innovations strong changes in production processes (upgrade or purchase of spinners, weavers, cutting machines…), clothing producers and fashion brands have every interest to embrace that concept, for several reasons.

First, connected fibers allows new uses and the rise of textile as a new connected device, such as your smartwatch or your tablet. The Jacquard Project, led by Google and Levi’s, is a striking example of that, without even thinking about the always growing number of connected shirts for heartbeat monitoring.

Second, they enable a better traceability, every clothes being able to carry within itself a code representing all information relative to its production (materials, place, serial number), its distribution (place and logistics), or even its purchase. You lost your sweater? You might be able to recover it very soon! In France, the start-up Primo1D, founded in 2013, is one of the specialists of this activity, based on a RFID-like technology called E-Thread. But they are not alone: famous fashion brands are taking the wheel, such as Ferragamo & Moncler, that unveiled a RFID-authentication system this year.

Finally, the question of counterfeiting is also one to ask: such clothes and accessories will be very easily identified thanks to cryptology methods that are complicated to copy, and thus bring a real added-value to fashion and luxury brands. Might be the perfect anti-counterfeiting weapon then!

With the rise of personalization, disintermediation and the IoT, the fashion industry will have to face several reinvention of its economic model within the next few years. With fashion designers willing to go niche-market and the still growing menace of counterfeiting from developing countries, new production processes has to be set in place, possibly accompanied with a partial relocation of activities to western countries, thanks to innovations.